I feel that the desired users of this object care about decoration and design, and would like to surround their office space with objects that reflect that intersection of interests.

The tape dispenser is constructed of aluminum. Since this is more of a premium product, it could be CNC’d out of a billet, then powder-coated for a glossy and durable finish.

I used Onshape to build my model, and my goal was to make it look as much like my sketches as possible, seen later, and hold a standard roll of Scotch tape.

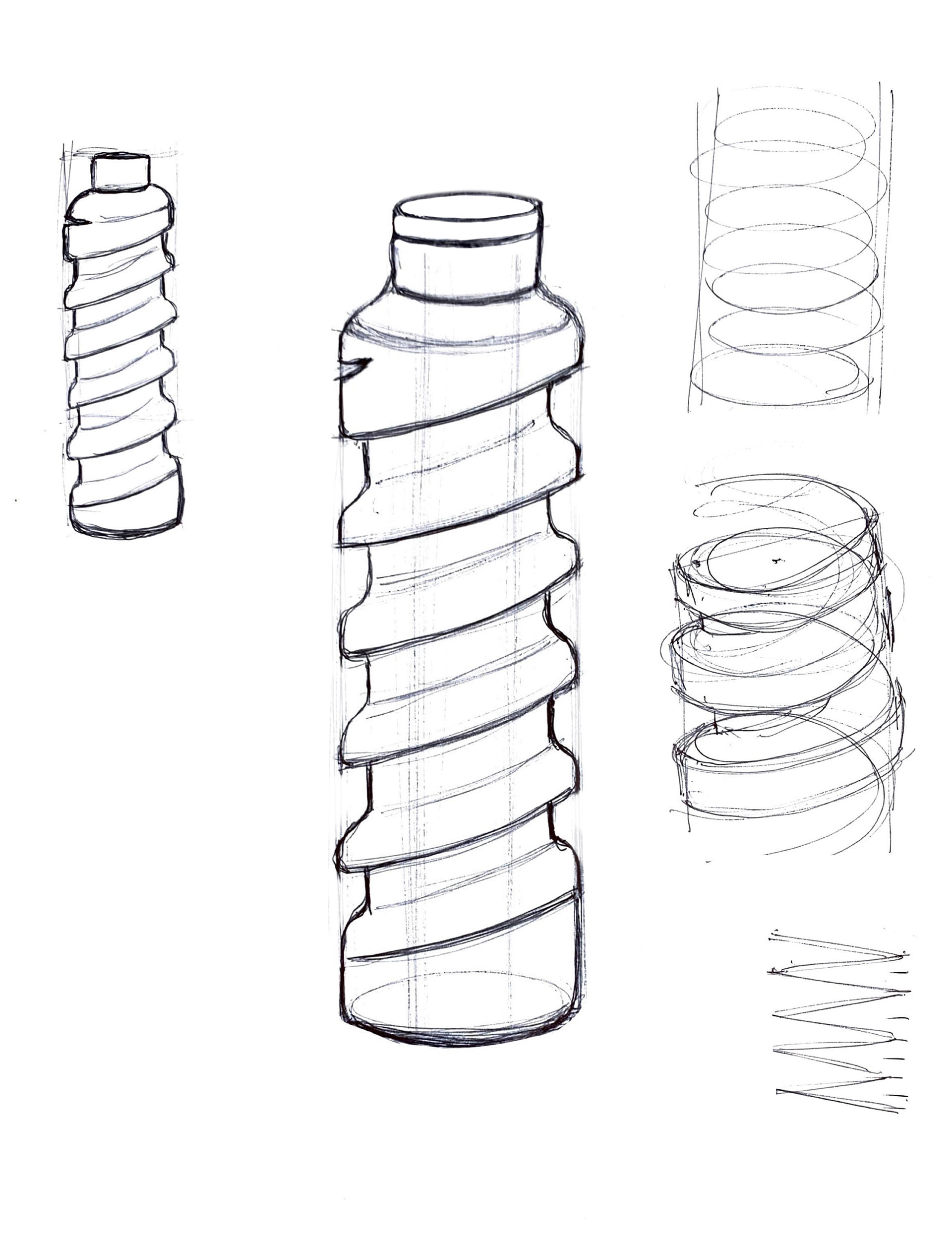

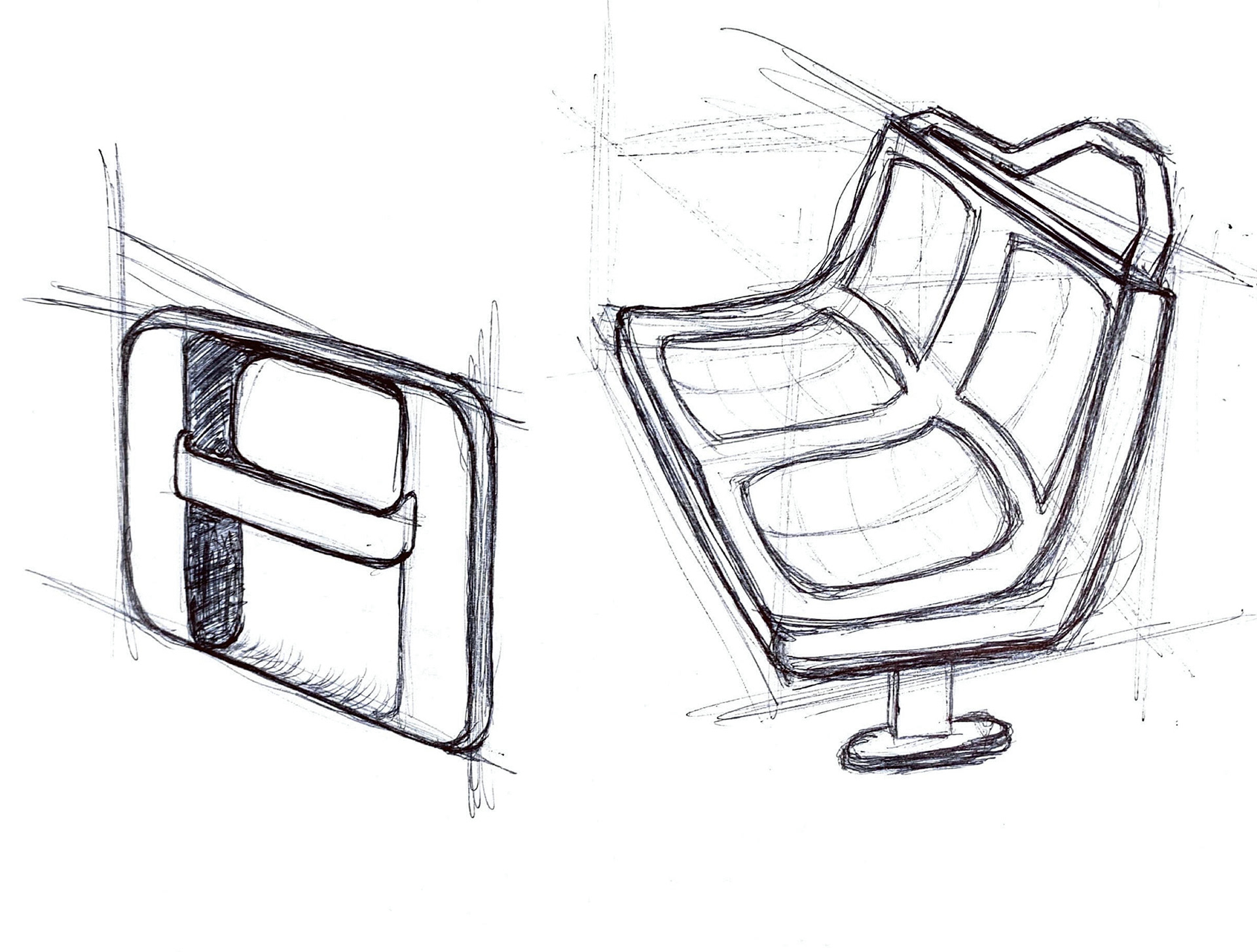

Below: My progress in learning to sketch for ID. My final sketches for this project are a result of me building upon the basics I learned in the course.

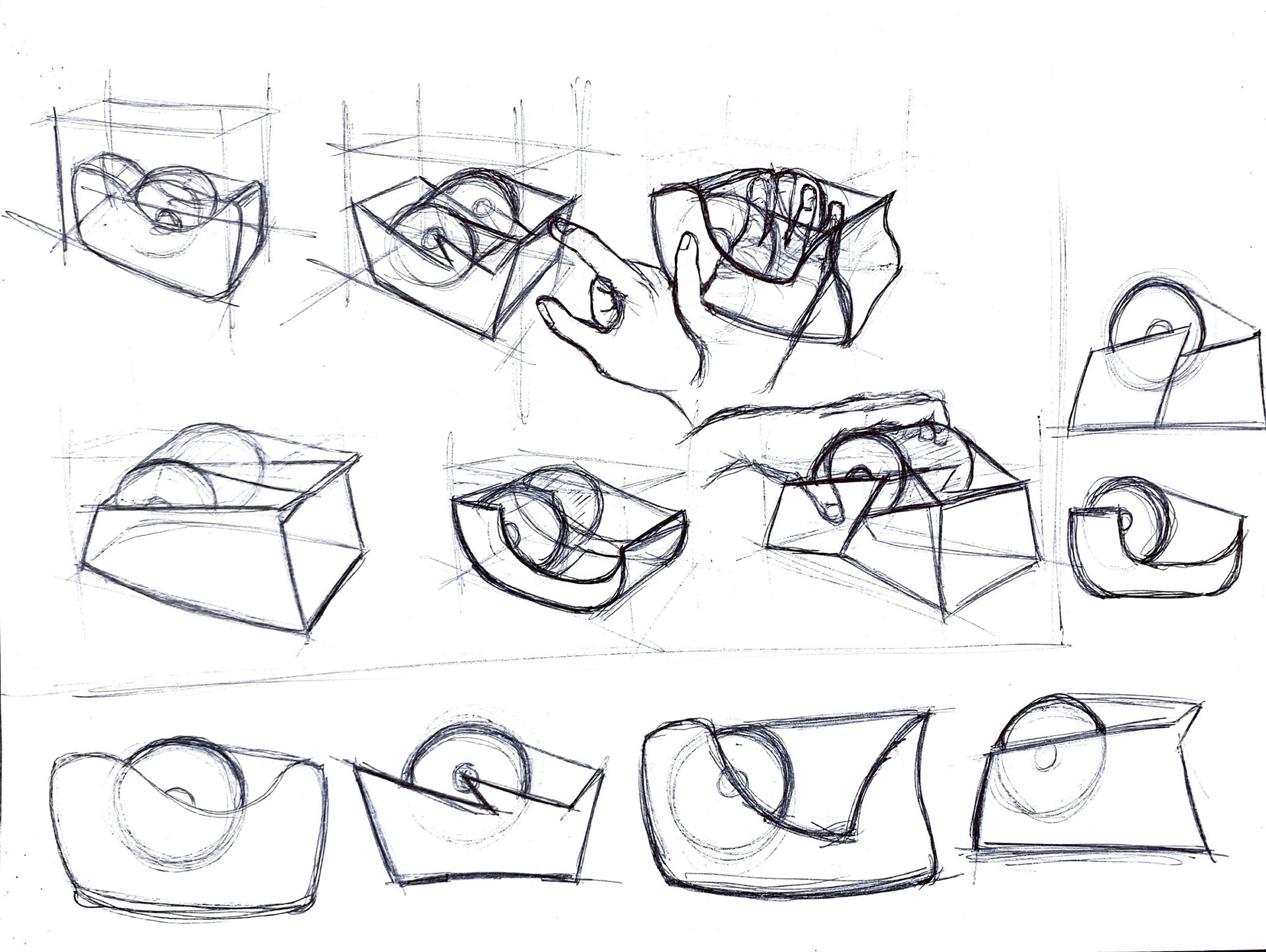

In order to build my skills further, I created multiple variations of tape dispensers. Based on these sketches, I set out to represent my ideas in CAD, as well as create something that would work with a pre-existing product—in this case, that product is a standard roll of scotch tape.

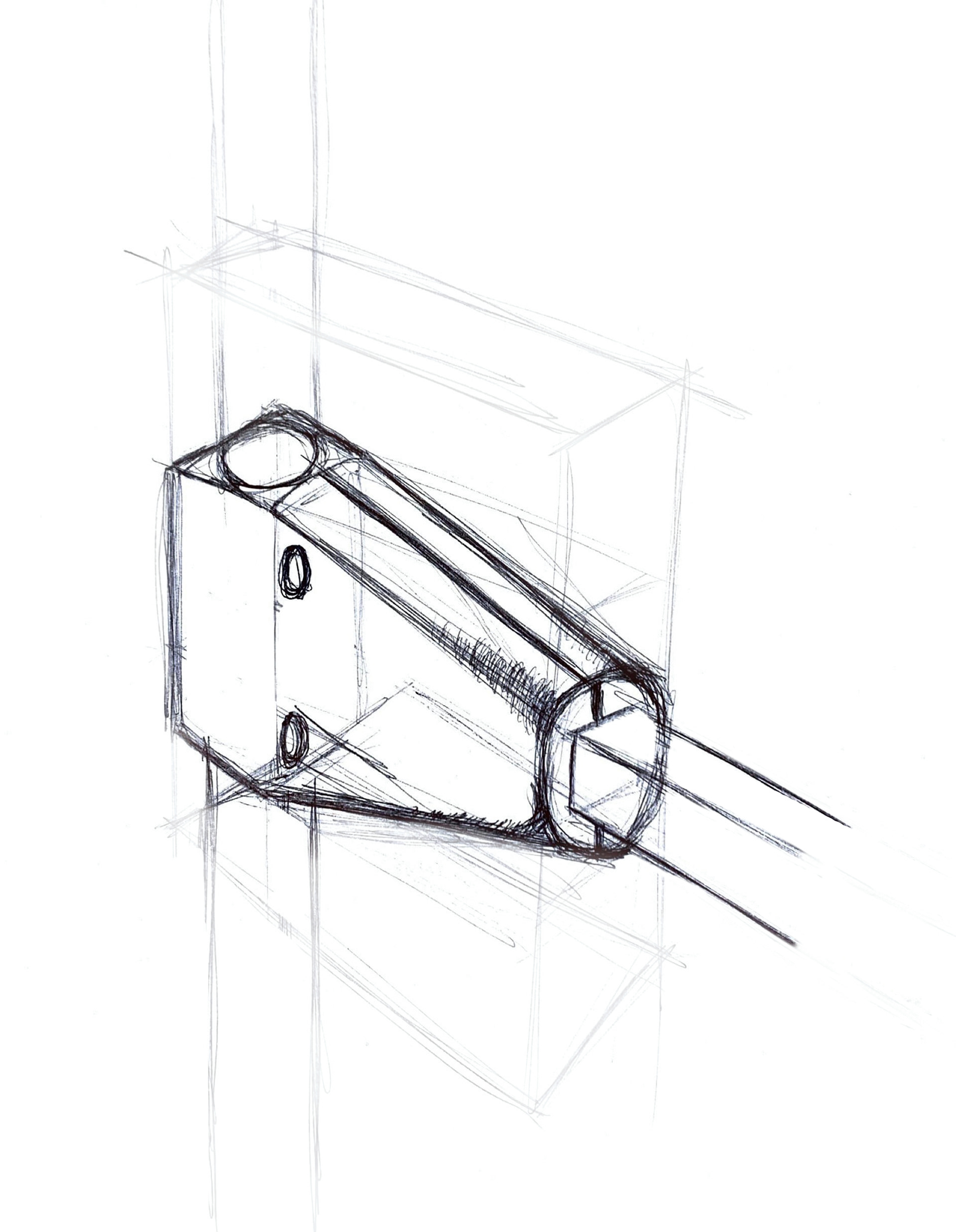

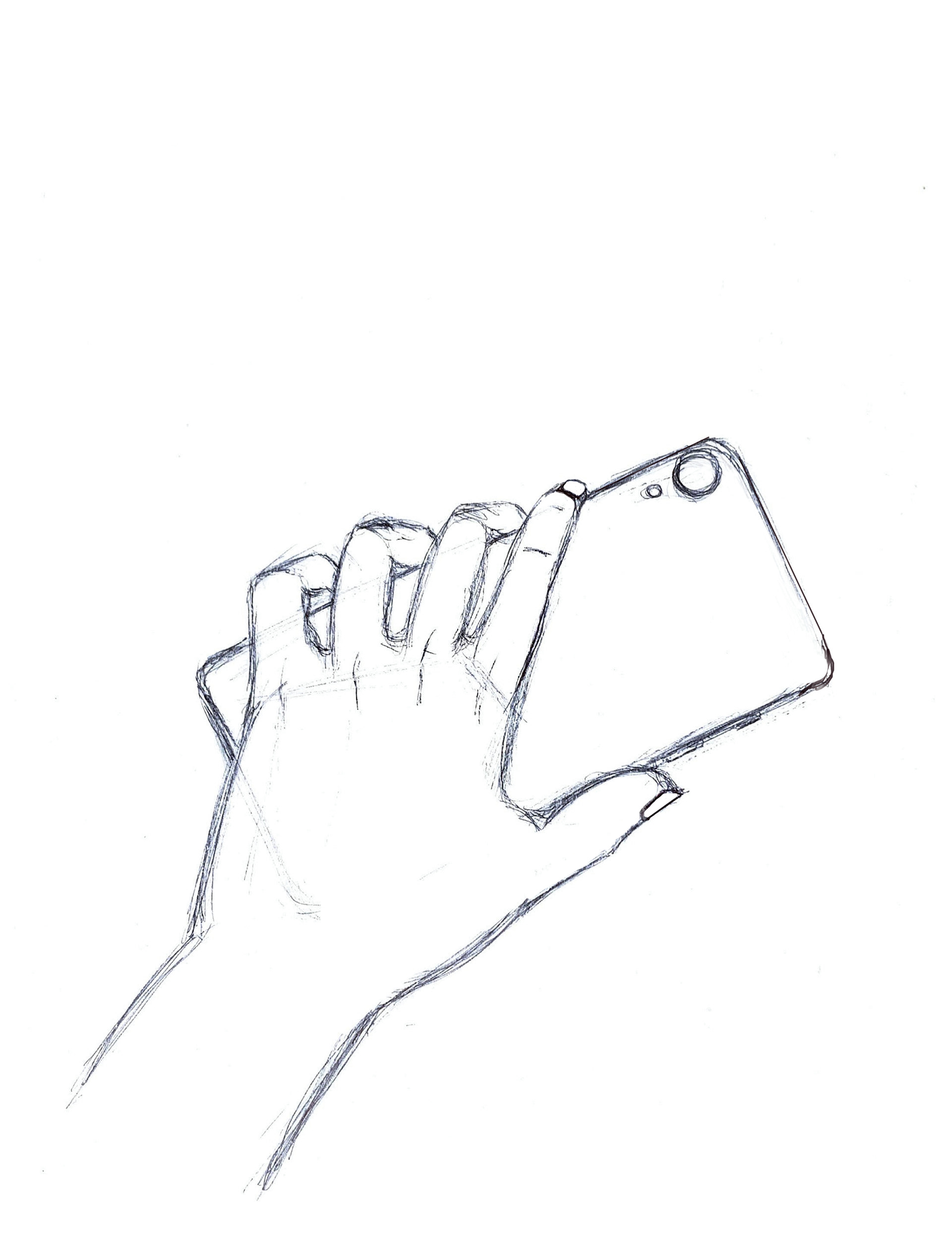

Below: Thumbnail sketches. Sketches featuring hands are my favorites.

Below: Final sketch that guided my CAD modeling.

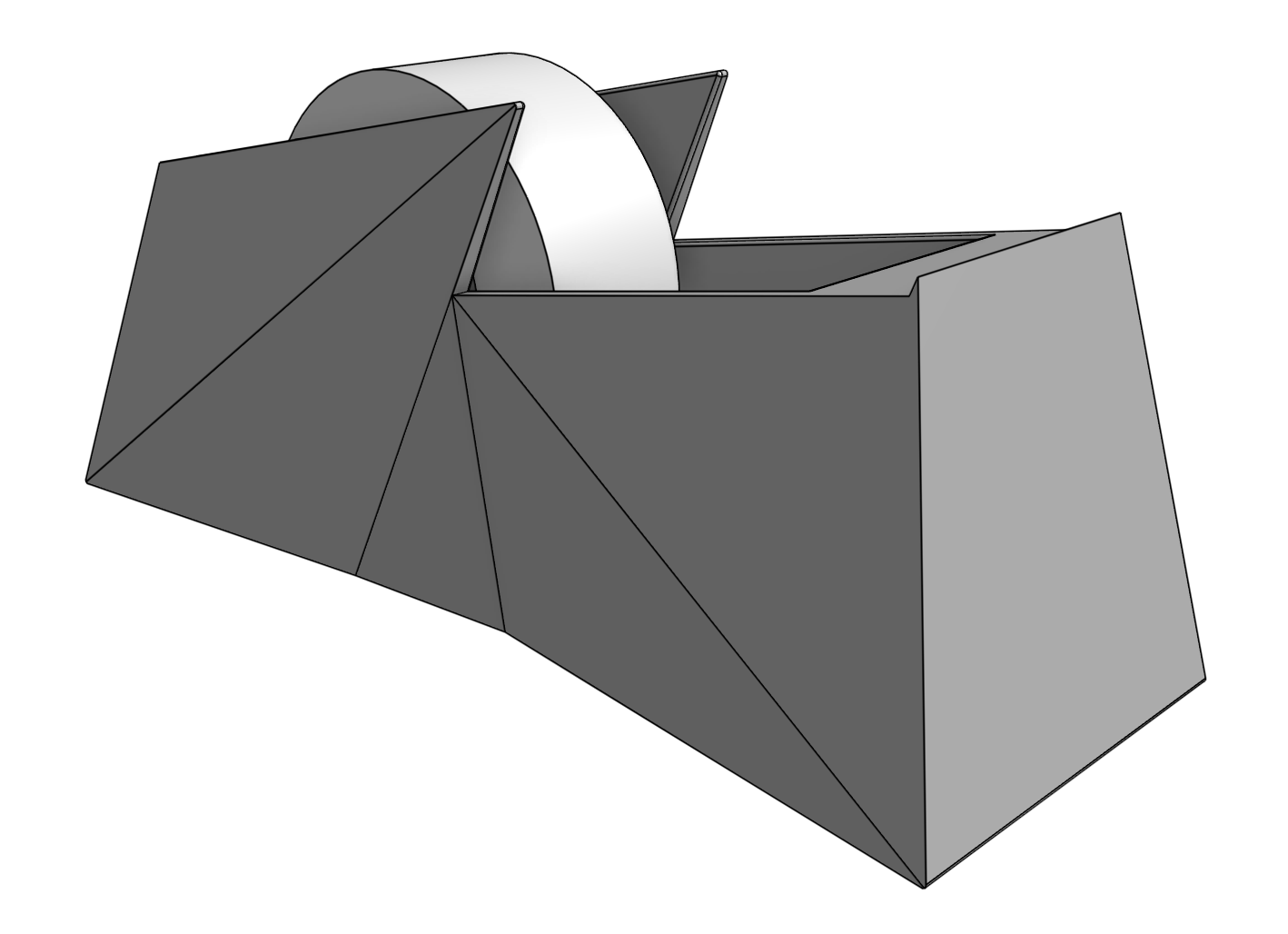

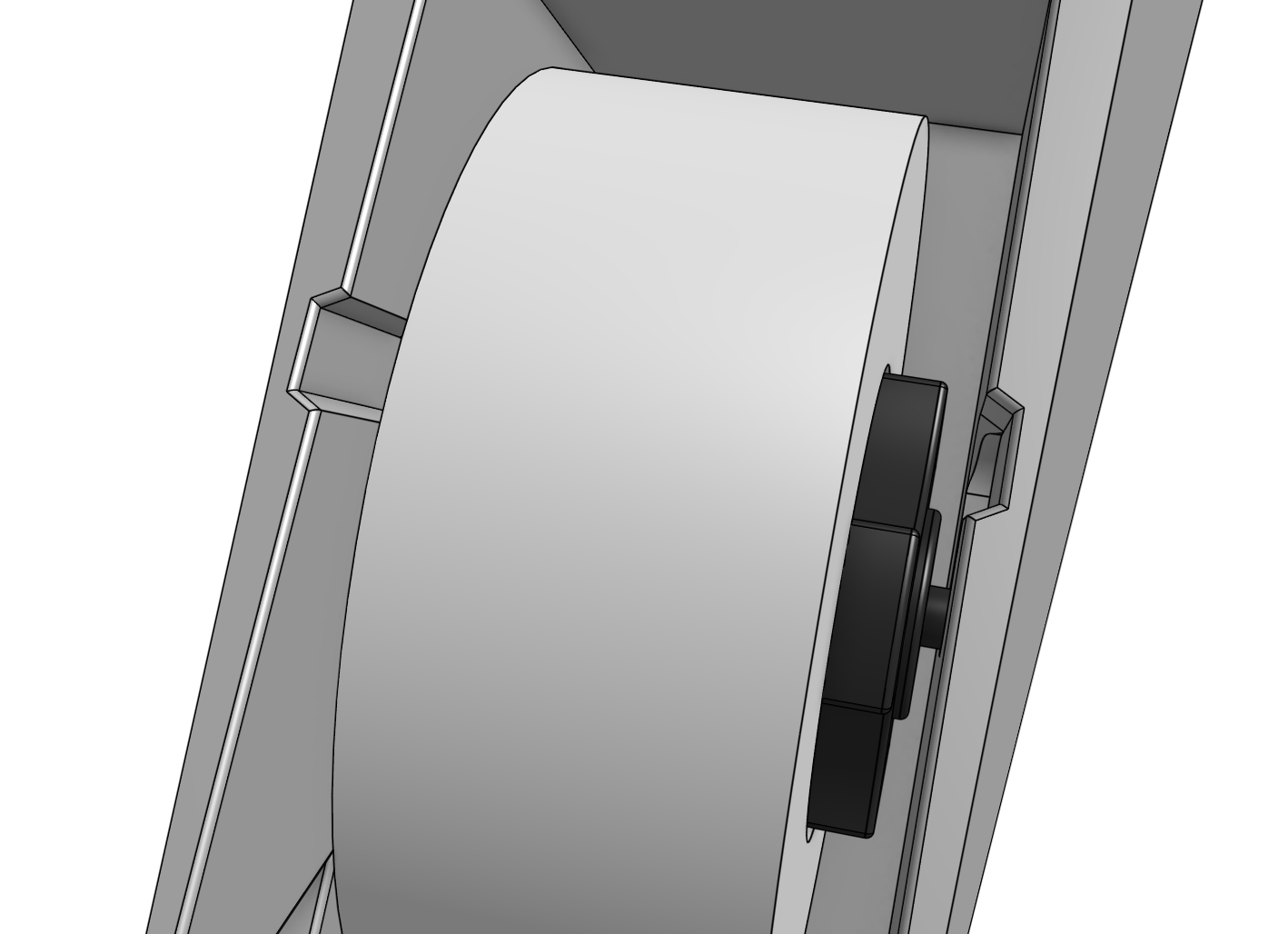

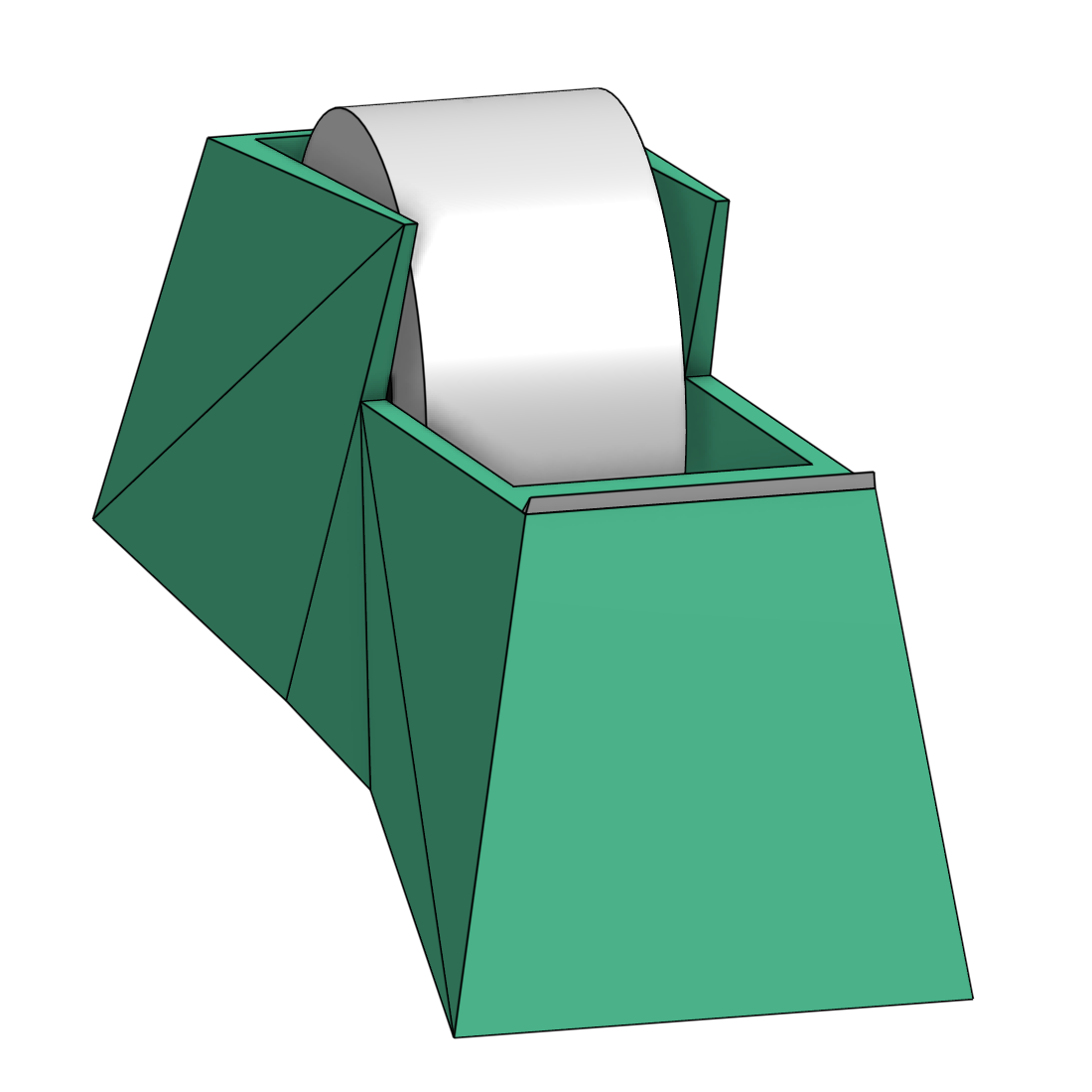

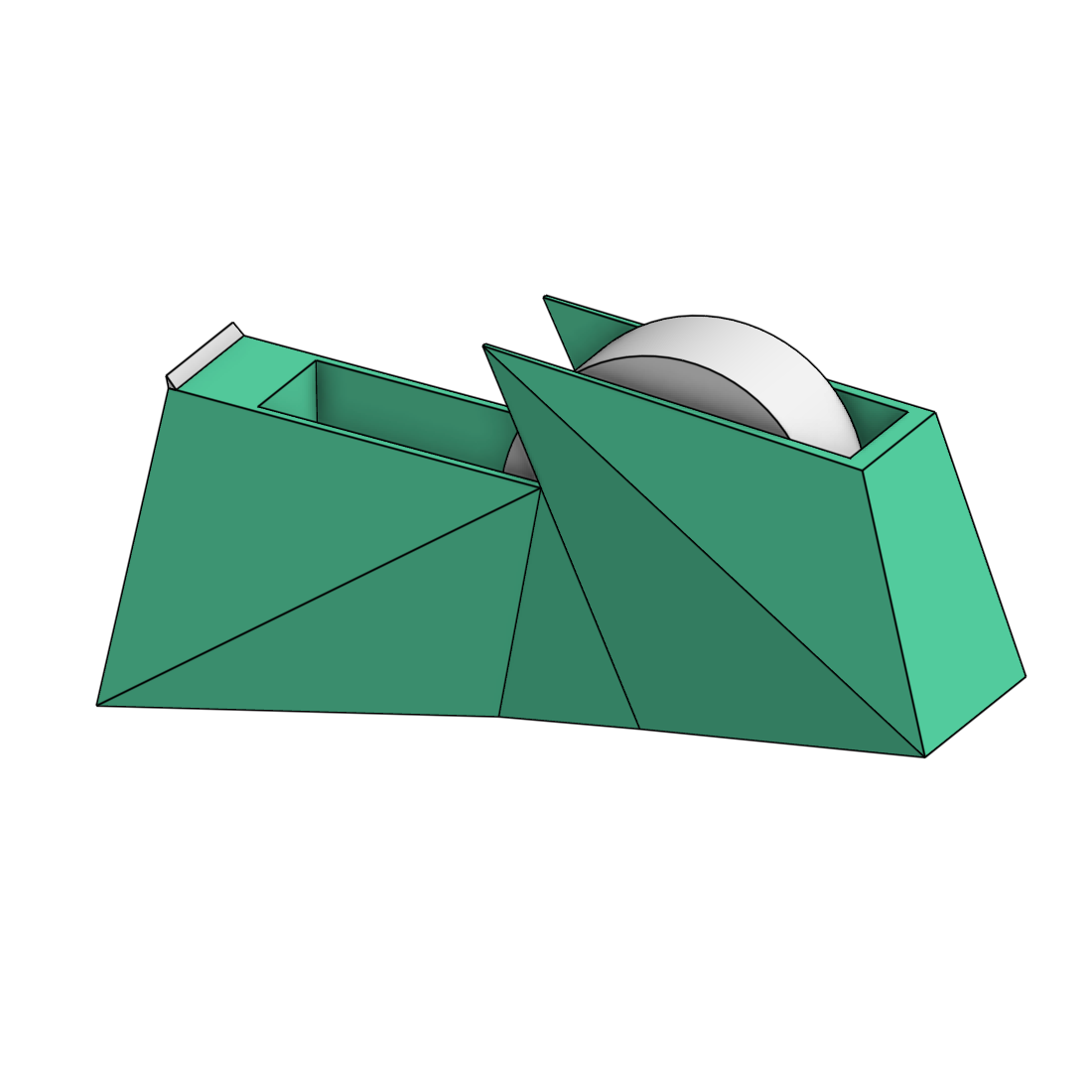

Below is my first CAD model. It features a cutter, a tape wheel, and a roll of tape as independent parts.

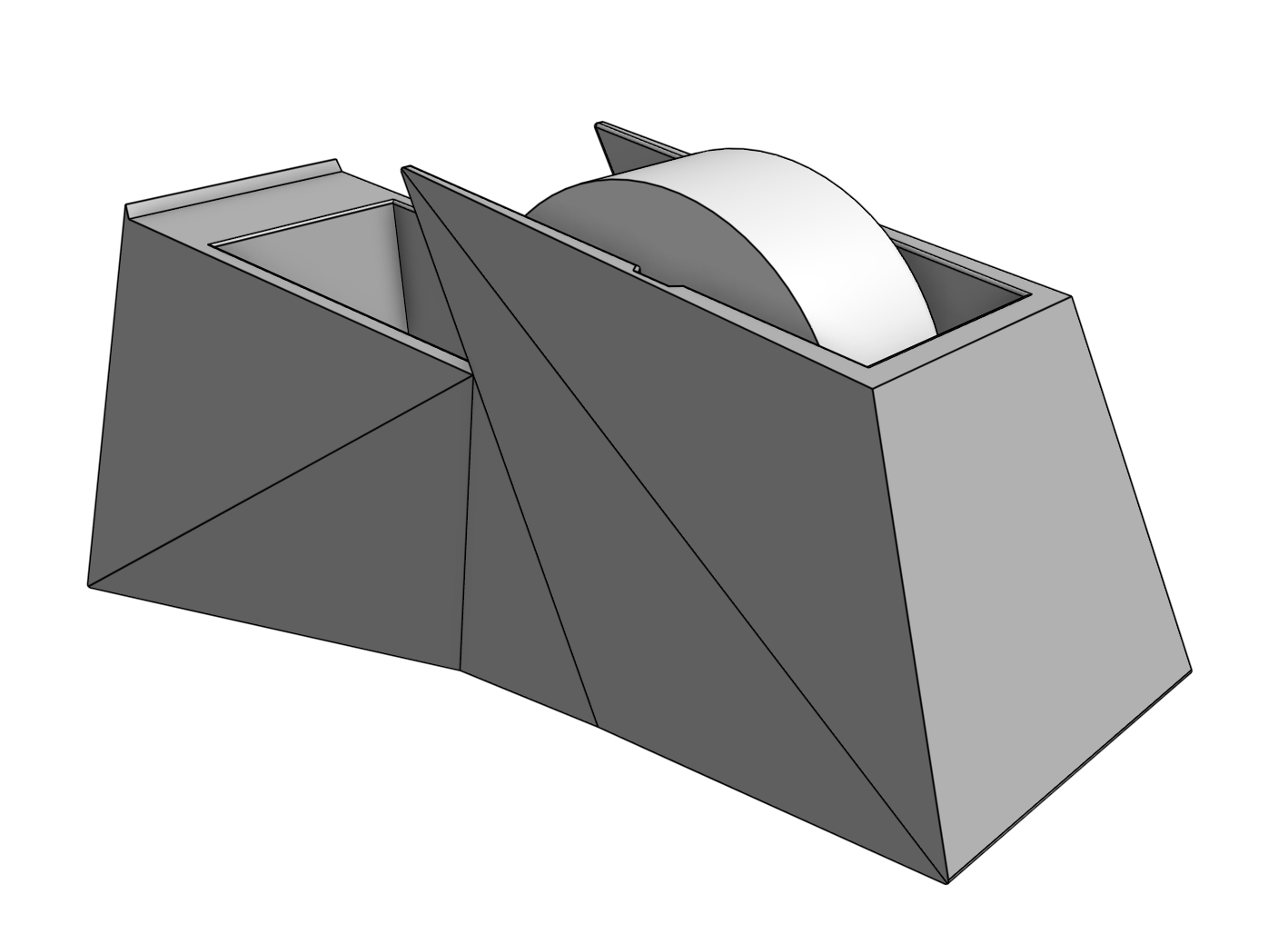

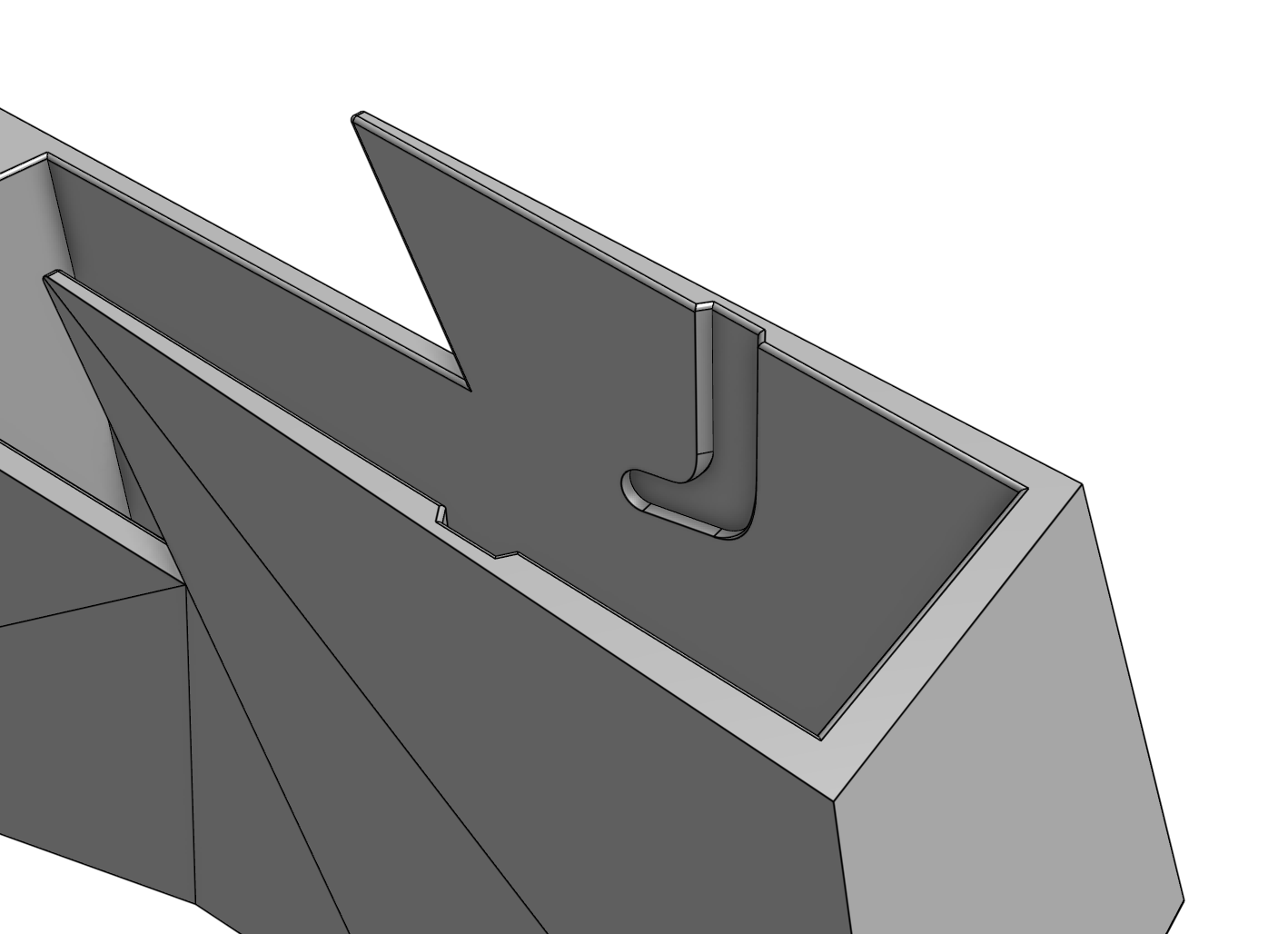

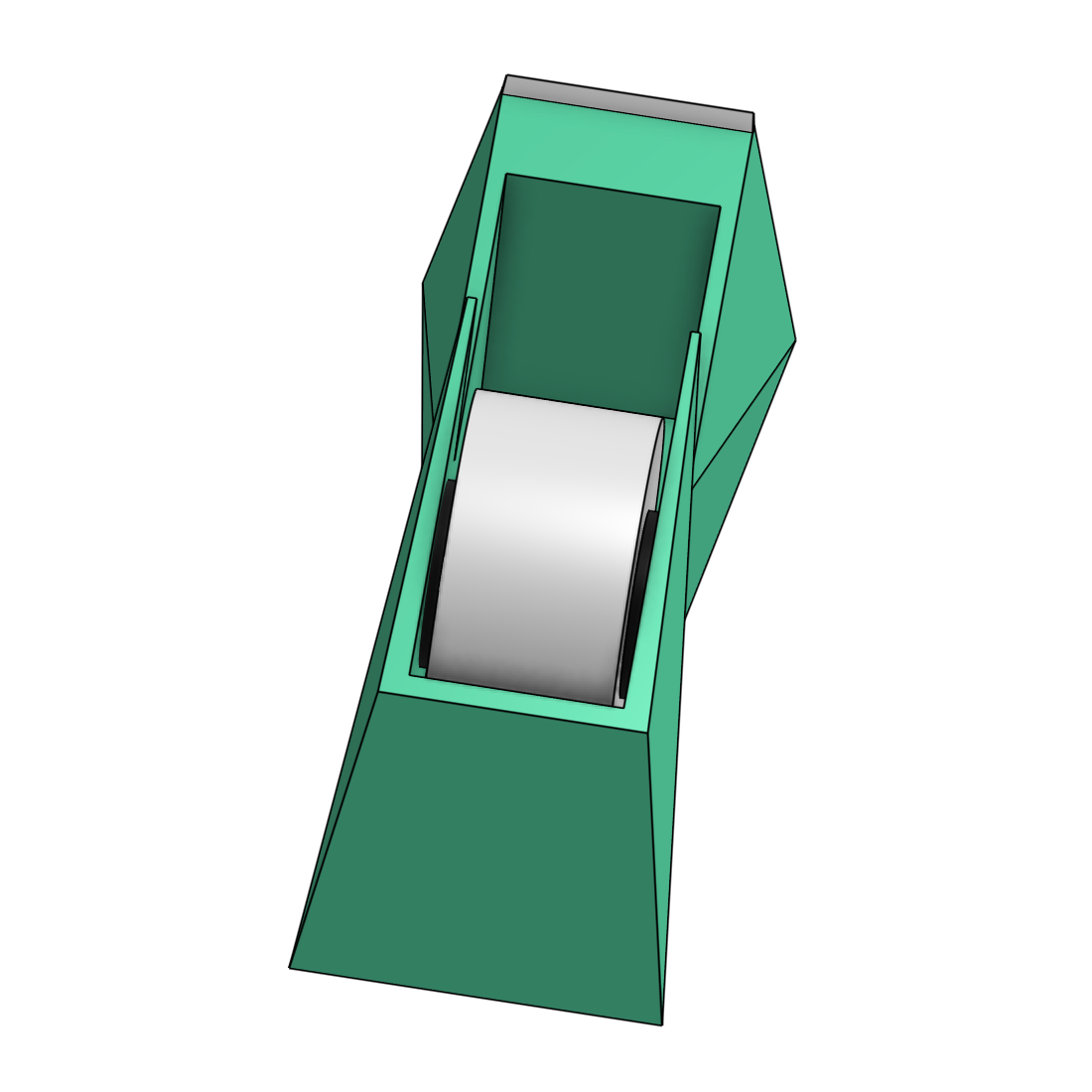

Here is my final model. I refined it further, thinking more about how it would work and the manufacturing process.

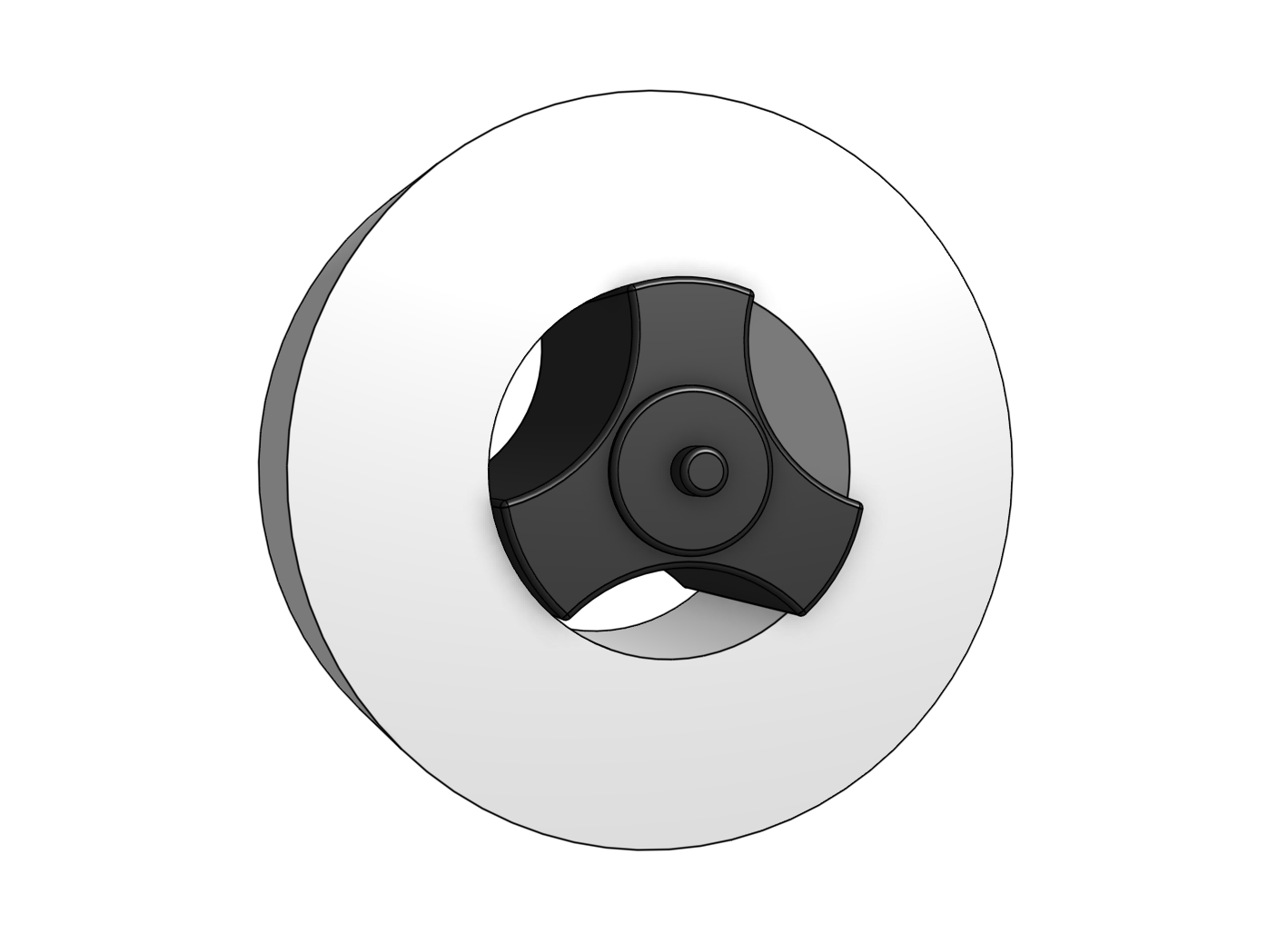

The tape cutter is now part of the body, and I modeled a groove for the tape wheel to slot into. I also finalized the tape wheel, ensuring it is accurate to similar objects in real life. The final touch was filleting some of edges of the model for a more lifelike look.